|

|

|

|

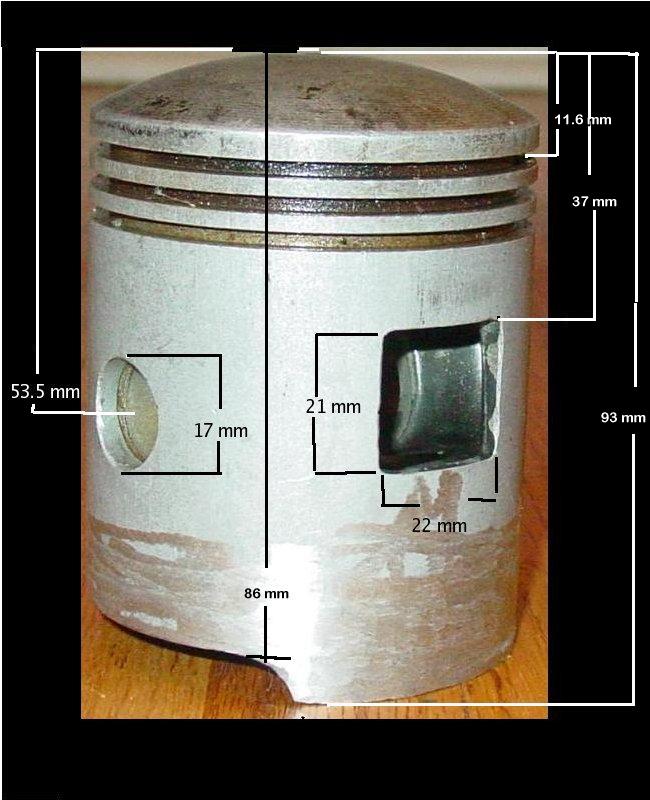

Above piston diagram sent in by David H with dimensions, see below for more dimensions and markings. Note vire 7 and Vire BVR pistons should be the same, but dealers are quoting £250 for spares and dont have them in stock - we wonder where they get them, if you can let us know, we will put the word out as this is a rip-off and rebuild-killing problem. Wartburg 311 car piston?? who knows. Stop press 2006, I can now offer OEM piston kit at a great price. Q> Why are the rings gummed up/piston seized? A> you didnt winterise properly. Q> How do you winterise A> run engine, turn off seacocks (fill engine with antifreeze if mooring freezes), remove plug, pour in half a cup (100ml) oil into piston, turn crank a couple of revs, leave piston at TDC (feel with screwdriver down plug hole), replace and tighten plug. Plug your exhaust with a bung to prevent corroding piston skirt through exhaust port. Q> How do i un-winterise A> (invariably the engine is installed making it nearly impossible to drain via drain bolt underneath crankcase) remove exhaust bung if fitted, remove spark plug, place rag around and over plug hole to catch ejected oil/water, turn over engine about 10 revs/10 seconds on the starter, replace plug with a new Champion L86c or Bosch W8AC gapped to 20 thou, (reconnect seacocks if you shut them/filled with anti-freeze), Removing Seized piston - technique: if your engine hasnt turned over for many months/years, getting the piston free is a nightmare, until now... make a spark plug with a grease nipple on the top(drill out to fit a pressed in alloy tube/tap to fit nipple)

tighten in the nipple/plug tool you made grease with a grease gun. hey presto - the crank will click as the rings unseize at last. now remove cylinder nuts and keep exercising the rings until you can slip it off the piston. If the rings are badly gummed, you might find it very tight the last inch, so try unscrewing' the cylinder as follows.. put the engine mounting in a vice so the engine is secure insert a suitable hammer shaft etc into the exhaust port. CAREFULLY and patiently, with plenty of diesel/penetrating fluid, use the shaft to give you more twisting leverage to the cylinder. warning - do not use excessive force as you will damage the little end bearing/ con rod. best of luck Removing stuck rings - technique: if you got your piston out and the rings dont look too bad, but are gummed in, you need to be patient and carefull to avoid breaking them./ I had success with some that were gummed in for 7 years - now working perfectly.. using small flat edged screwdriver about as big as the ring width, carefully try to loosen the ends of the rings with a little leverage. IF you see piston ring 2" away moving as you do this - carry on until you can put the flat blade between the piston and ring, then progressively turn the blade 90 degrees toward the embedded end og the ring, and then slide it a bit further. IF YOU DONT then stop, since you will certainly snap the ring. use a blow torch to heat the piston to about 180-220 degrees celsius (spit boils instantly), then being

careful not to burn yourself or drop the piston, try again. dont overheat the piston as it will melt/ soften, and

never heat partiall free ring, as it will overheat quickly and 'temper' losing its neccesary hardness. if it still wont budge, allow to cool, re-soak in diesel, and repeat in a few hours. you will find that after a few re-heats the expansion of the piston/contraction is breaking down most of the scale/alluminium oxide that is between the ring and the piston. when you removed your stuck rings succefully, clean them up with a knife scraper, and palming them on fine al02 sandpaper. clean out the piston grooves with a stanley knife, and loose hacksaw blade(gently) finally make sure the grooves are finished by rolling the rings around the piston while the touching outside edge of the ring is completely within the groove.

invert piston in a jar of diesel overnight to at least cover rings.

Here are some photos of a (damaged but running order) standard piston from a Vire 6

"it had just one fault - it occasionaly cut out for no reason, then when we stripped it, we found the cutout switch in the cranksace was faulty/loose so that was probably its only problem" I was expecting a good piston, cylinder and crank, but i found to my dissapointment, the piston had been seized, the cylinder scored, and the crank big end had excessive play, as well as rusted main bearings!

FYI the piston, may be obtainable as a cheap spare, as I have heard it is the same as an early East German 2T car the 'wartburg 311'. I contacted the webmaster for a Wartburg / travant site, and his comments sounded promising!

above: the markings on th crown are "69.79" (mm dia) and "X2" (VIRE6) Bore 2.75" (69.85mm) Stroke 70mm, 268cc, top ring chromium plated(VIRE6) low expanion alluminum alloy I really hope we can pull together and solve this problem as the rings from fairways are in short supply, and ridiculously priced. a travant ring set - if the same would only cost a few pounds through the club. If you know any piston/rings info for compatible parts please email me from the contact page - I will publish the results here and elsewhere.

|

| [Vire 7 Marine Engine] [How To] [Manuals] [FAQ] [Special Deals] [Contact] [Buy Parts] [Vire 12] |

they came from a Westerly Warwick (21), whose owner removed, stripped and

discarded the engine because

they came from a Westerly Warwick (21), whose owner removed, stripped and

discarded the engine because